Home » Basics

First: for an AC machine, rotational speed is directly proportional to frequency. This means that higher frequencies mean higher speeds.

Second: output torque is proportional to the square of the voltage. This means if you lower the voltage, the torque will drop even more.

Third: for the same power draw, current is inversely proportional to voltage. This means that at the same power output, a lower voltage machine will require more current.

Second: output torque is proportional to the square of the voltage. This means if you lower the voltage, the torque will drop even more.

Third: for the same power draw, current is inversely proportional to voltage. This means that at the same power output, a lower voltage machine will require more current.

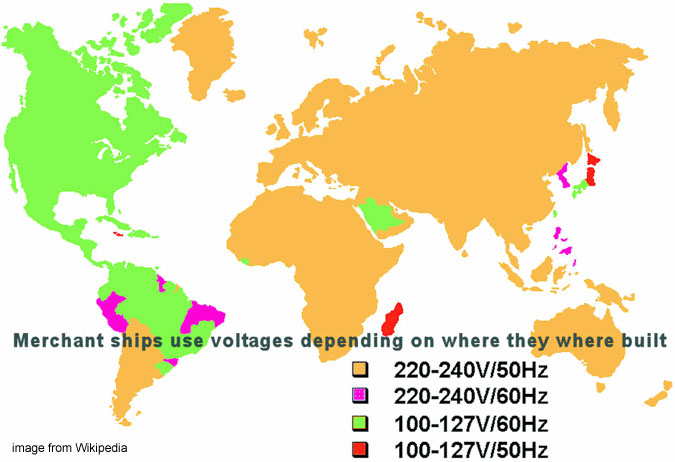

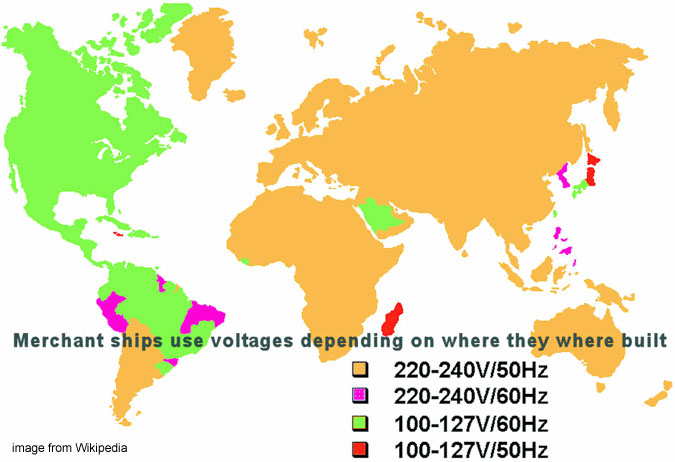

The world's main supplies electricity (AC) voltages are different from countries to countries, generally are 110V (120V) and 220V (230V, 240V). The operation frequency is typically 60Hz at 110v in USA/Canada while European/Asian countries use 220v 50Hz.

Why did the countries choose the voltage and frequency?

Is there any special case?

What will happen if you use your appliances in other countries?

This article will explain in brief.

Why did the countries choose the voltage and frequency?

Is there any special case?

What will happen if you use your appliances in other countries?

This article will explain in brief.

There is no "best" frequency or voltage. Everything requires some trade-off in performance or manufacturability.

In historically 50 Hz and 60 Hz is relatively same than low frequency 25 Hz or high frequency 133 Hz was appear and in operate. If you have Japan reference, there are use 50 Hz and 60 Hz power supplies with HVDC back To back. In electronic developing, specially some applications use until 400 Hz, see on electrical system Of aircraft and marine.

60 Hz machines tend to operate at slightly higher speeds - or have a slightly more complex mechanical arrangement (more poles) compared to 50 Hz equipment. Is that better or worse? Depends on what is being weighed in the equation.

In historically 50 Hz and 60 Hz is relatively same than low frequency 25 Hz or high frequency 133 Hz was appear and in operate. If you have Japan reference, there are use 50 Hz and 60 Hz power supplies with HVDC back To back. In electronic developing, specially some applications use until 400 Hz, see on electrical system Of aircraft and marine.

60 Hz machines tend to operate at slightly higher speeds - or have a slightly more complex mechanical arrangement (more poles) compared to 50 Hz equipment. Is that better or worse? Depends on what is being weighed in the equation.

Tags: 50Hz vs 60Hz

Residential power in the US is usually provided by the center tapped secondary of a distribution transformer. Two wires are hot, 120V at 180 degrees out of phase therefore 240V when used together. For 120V there is another neutral wire. Connecting either hot wire and the neutral provides 120V. This is how most modern US homes are wired. The 240V is used only for high wattage appliances like clothes dryers or water heaters.

There is nothing magic about three phase. Almost all power systems all over the world generate three-phase high voltage electricity at 50 or 60 Hz. For home or business use, many appliances and machines are single phase at 120 or 240 volts, using one phase of the three phase system. Large machinery uses three phase at 240 or a higher voltage. A variable speed drive with a 208Y/120 output could be used to operate 120v equipment but it would be "overkill" unless you had several appliances and kept the phases balanced with about the same load.

There is nothing magic about three phase. Almost all power systems all over the world generate three-phase high voltage electricity at 50 or 60 Hz. For home or business use, many appliances and machines are single phase at 120 or 240 volts, using one phase of the three phase system. Large machinery uses three phase at 240 or a higher voltage. A variable speed drive with a 208Y/120 output could be used to operate 120v equipment but it would be "overkill" unless you had several appliances and kept the phases balanced with about the same load.

Since the intent is to retain the same voltage, the stator winding itself will have to change. The objective is to have the same number of coils (or turns) cutting the same number of lines of flux. Again, the ratio of frequencies is relative to the change in number of turns. (In your case, a 5 turn coil would become a 6 turn coil). With the slot geometry limited to a fixed value, this means smaller cross-section and increased heating - or a derate of the output power by the same ratio (180 kW at 50 Hz becomes 150 kW at 60 Hz).

In general with a small inverter rated motor, provided the current is less than the rated full load amps, it can be run over a very wide range. This has the net result that the motor has a fixed torque limit over all speeds, hence the available shaft power varies with speed, so a 5kw 50Hz motor can deliver 4kw at 40Hz, and 6kw when the frequency change to 60Hz.

As the heat in the motor varies with the load current squared, most practitioners will simple derate the motor slightly. For example if you have a 4kw mechanical load, then use a 5kw 60hz motor, and simply tell the variable frequency drive the FLA is 5/6 of the nameplate amps. The heat in the motor will be 25/36 of its 5kW rating or 69.4%, this massive reduction in heat load will enable trouble free operation from standstill to nearly twice nameplate rpm. It's a simple solution: change to the next size up motor. The difference in cost is probably less than the cost of an hour of your time anguishing over what to do.

As the heat in the motor varies with the load current squared, most practitioners will simple derate the motor slightly. For example if you have a 4kw mechanical load, then use a 5kw 60hz motor, and simply tell the variable frequency drive the FLA is 5/6 of the nameplate amps. The heat in the motor will be 25/36 of its 5kW rating or 69.4%, this massive reduction in heat load will enable trouble free operation from standstill to nearly twice nameplate rpm. It's a simple solution: change to the next size up motor. The difference in cost is probably less than the cost of an hour of your time anguishing over what to do.

Motors, like transformers need more iron as the frequency goes down. The alternative is to reduce the terminal voltage keeping the amount of iron the same. So, a US 60Hz 480 volt motor would work OK on a European 380 volt or Asian 400 volt system at 50 Hz ok. Because the torque is a function of frame size, the developed torque remains the same, but the reduced speed reduces the rated power by 50Hz/60Hz.

Motors, like transformers need more iron as the frequency goes down. The alternative is to reduce the terminal voltage keeping the amount of iron the same. So, a US 60Hz 480 volt motor would work OK on a European 380 volt or Asian 400 volt system at 50 Hz ok. Because the torque is a function of frame size, the developed torque remains the same, but the reduced speed reduces the rated power by 50Hz/60Hz.If 50 Hz supply is connected to 60 Hz motor the flux density increases more than rated and the motor may be burned but if the opposite case happens the motor will not work properly and the speed decreases less than rated.

For the same motor all the parameters are constant except the frequency and this will affect the applied voltage, so simply apply this equation and see what will happen:

This is the new required voltage to be applied to get the same motor duty as before.

As you see the voltage should raise to get also the same power as before, if not the motor will consume more current and become hotter. I mean you can imagine if you have a motor running on less voltage of what is recorded on his nameplate, what will happen to it? This is exactly what will happen in this case.

V1/f1=V2/f2, V1=400v (for example), andThen, the new voltage to be applied V2= 400x60/50=480v.

f1= 50Hz,

f2=60Hz.

This is the new required voltage to be applied to get the same motor duty as before.

As you see the voltage should raise to get also the same power as before, if not the motor will consume more current and become hotter. I mean you can imagine if you have a motor running on less voltage of what is recorded on his nameplate, what will happen to it? This is exactly what will happen in this case.

50Hz was standardized and used first for land based systems but marine generators were standardized on 60Hz. I have never read 'actually why' there was a chosen difference but at 60Hz your alternator is a little smaller and lighter. Today, even in 50Hz territories, you will find ship-to-shore and shore-to-ship 50/60Hz converters in harbors and all ships are 60Hz even European ones. You can extend the same argument to aircraft and airport ground-power supplies - those are 400Hz (441Hz to be pedantic). This means that generators for aircraft auxiliary power loads are very small and light (useful for flying!). That also explains why early data-centers were 441Hz - IBM designed to aircraft technology, even in 60Hz land. I can only assume that the US followed ships rather than England!

These standards for the 50Hz/60Hz frequency have been established when they have tested on carbon lamps. The idea was that the lamp must not flick. Indeed it was the flicker that decided the standard of the frequency in Germany 50Hz and in USA 60Hz. It seems that the lamp in Germany was smaller (therefore, the flicking phenomena was slower due to the slower temperature dissipation inside the lamp). Therefore, they have chosen 50 Hz.

These standards for the 50Hz/60Hz frequency have been established when they have tested on carbon lamps. The idea was that the lamp must not flick. Indeed it was the flicker that decided the standard of the frequency in Germany 50Hz and in USA 60Hz. It seems that the lamp in Germany was smaller (therefore, the flicking phenomena was slower due to the slower temperature dissipation inside the lamp). Therefore, they have chosen 50 Hz.

Tags: 50Hz vs 60Hz

There are some frequency converters that can convert 60Hz to 50Hz, or vice, but it's too costy to be used for home appliances, it would be better if there is an economic way to run 50Hz electrical appliances on 60Hz system.

Well for one thing, the 110v 60Hz electrical appliance will blow the fuse and also the power supply. 220v 50Hz appliance might start up, and burn the PC board as supply voltage is too low for that appliance. It depends upon the nature of the appliance but generally speaking if the voltage is too high it draws too much current and burns out, if the voltage is too low it draws too little current and/or does not perform to its rating. The mathematical reference is Ohm's Law and the Power Triangle.

Well for one thing, the 110v 60Hz electrical appliance will blow the fuse and also the power supply. 220v 50Hz appliance might start up, and burn the PC board as supply voltage is too low for that appliance. It depends upon the nature of the appliance but generally speaking if the voltage is too high it draws too much current and burns out, if the voltage is too low it draws too little current and/or does not perform to its rating. The mathematical reference is Ohm's Law and the Power Triangle.

50Hz 60Hz Frequency Converter Setting

Using GoHz frequency converter to

Or customize your own converters.

- Convert 220v 50Hz to 110v 60Hz,

- Convert 120v 60Hz to 230v 50Hz,

- Convert 110v 60Hz to 240v 50Hz,

- Convert 480v 60Hz to 380v 50Hz,

- Convert 400v 50Hz to 460v 60Hz,

- Convert 240v 60Hz to 380v 50Hz,

Or customize your own converters.

Featured Articles

460v 60Hz motor on 400v 50Hz power ...

Often the European motors at 1hp size are universal for 50Hz or 60Hz power supply, as long as you have 400V x 50Hz and 460V x ...

Often the European motors at 1hp size are universal for 50Hz or 60Hz power supply, as long as you have 400V x 50Hz and 460V x ...

Often the European motors at 1hp size are universal for 50Hz or 60Hz power supply, as long as you have 400V x 50Hz and 460V x ...

Often the European motors at 1hp size are universal for 50Hz or 60Hz power supply, as long as you have 400V x 50Hz and 460V x ...Convert 220v, 230v, 240v 50Hz to 110v, ...

When you buy an 110v (120v) 60Hz appliance from USA, and run it on 220v (230v, 240v) 50Hz country (i.e. UK, Australia, ...

When you buy an 110v (120v) 60Hz appliance from USA, and run it on 220v (230v, 240v) 50Hz country (i.e. UK, Australia, ...

When you buy an 110v (120v) 60Hz appliance from USA, and run it on 220v (230v, 240v) 50Hz country (i.e. UK, Australia, ...

When you buy an 110v (120v) 60Hz appliance from USA, and run it on 220v (230v, 240v) 50Hz country (i.e. UK, Australia, ...60Hz motor running on 50Hz power ...

Electric motors, both single and three phase, are designed for running on a specified power frequency. But sometimes we may use a ...

Electric motors, both single and three phase, are designed for running on a specified power frequency. But sometimes we may use a ...

Electric motors, both single and three phase, are designed for running on a specified power frequency. But sometimes we may use a ...

Electric motors, both single and three phase, are designed for running on a specified power frequency. But sometimes we may use a ...